Vibrating Fork Level Switch/Controller

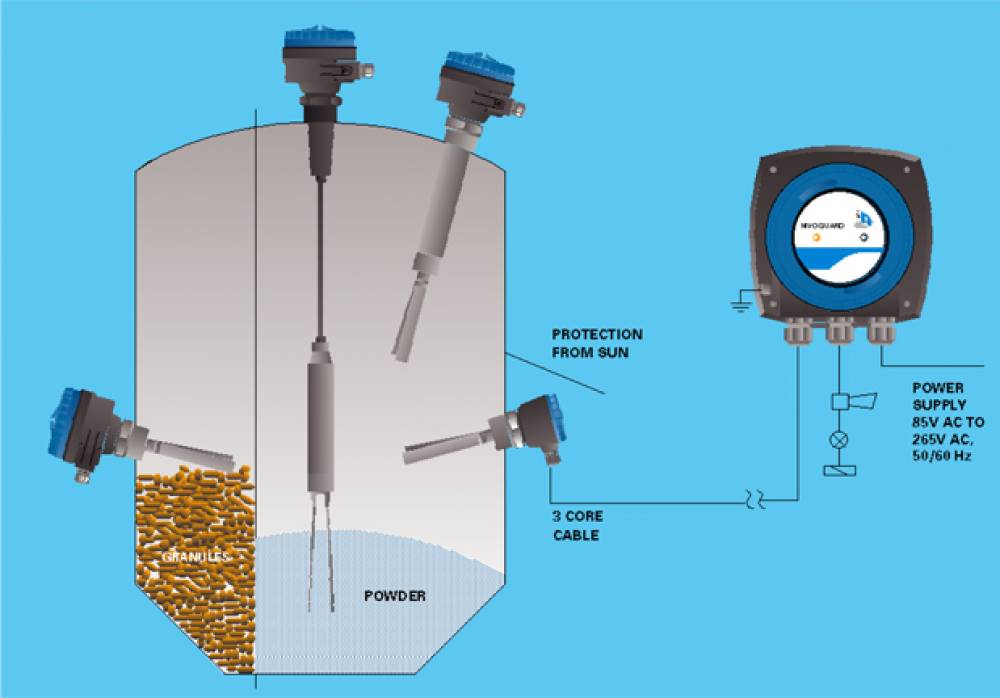

A Vibrating Fork Level Switch/Controller is a reliable, non-contact device used to monitor and control the level of materials (liquids, powders, or solids) within a container or tank. It operates based on the principle of a vibrating fork, which changes its vibration frequency when it comes into contact with a material.

How it works:

- The device has a fork or prong that is vibrated at a specific frequency by an integrated piezoelectric crystal or actuator.

- When the fork is exposed to the material being measured, the vibration frequency changes due to the added mass, which is detected by the controller.

- The controller then interprets this frequency change to determine whether the material has reached a high or low point, sending a signal to either trigger an alarm or control a valve or pump to maintain the desired level.

Key Features:

- Simple, reliable operation: No moving parts in contact with the material, reducing wear and tear.

- Versatility: Suitable for a wide range of materials, including liquids, powders, granules, and slurries.

- High accuracy: Provides precise level measurements, ensuring that systems are not overfilled or run dry.

- Durable: Resistant to extreme temperatures, pressures, and harsh environments, making it ideal for industrial applications.

- Easy installation and maintenance: Compact, self-contained, and requiring minimal maintenance.

Applications:

Vibrating Fork Level Switches/Controllers are used in various industries, such as chemicals, food processing, pharmaceuticals, water treatment, and oil & gas, for applications like high and low-level detection, overfill prevention, and dry run protection in tanks, silos, and vessels.